Metal Parts and Precision

GK continues to invest in the latest machining centers and advanced software for the purpose of continuous improvement and to be a leader in machining technology. GK Machine has the expert technicians on staff with education and training on CNC processes and procedures to meet high standards of excellence for precision machining.

With GK’s one-stop shop, there is no need to go to various vendors for your metal production needs. With state-of-the-are machines to design, create and manufacturer metal products, GK offers a wide variety of metal manufacturing services:

- Laser Cutting

- Welding & Fabrication

- Integrated Electrical Assembly

- CNC Machining

- Plasma/Flame Cutting

- Metal Forming

- Mechanical Assembly

- Finishing (prep, wash, paint & powder coat)

GK Provide full service contract manufacturing, metal machining and fabrication services for a variety of industries:

- Agriculture

- Industrial

- Forestry

- Motorsports

- Waste Management

- Food Processing

- Transportation

- Energy/Fuel

- Government Agencies

Part Design & Modeling

GK can assist you with the design and modeling of custom Metal Parts and Precision Components. We have the ability to design, create and model parts in a 3D environment in order to provide detailed measurements and specifications for your metal part or piece. GK has been using MasterCam 3D software and AutoDesk for product design for more than 20 years and several of our employees are MasterCam certified.

We use a simple 4-step process to part design:

1. Explore and understand client requirements. GK begins with a review of materials, manufacturing processes, design considerations, and finishing options for metal prototypes and low-volume or high-volume production parts.

- Hole depths and diameters

- Text on parts

- Live-tool lathes

- Size and types of thread

- Heights and feature widths

- Multi-axis milling

2. Plan and review concepts with customer. 3D CAD files are created by an engineer and/or machinist based on the overall review of the metal part or piece in order to review details of measurement and specifications.

3. Client authorizes work and then all files are converted into machine code, which controls a machine to precisely mill or turn into the final part. Parts now go into manufacturing production.

4. Project conclusion is the final stage, we measure and quality checks all parts/pieces before shipping directly to the customer.

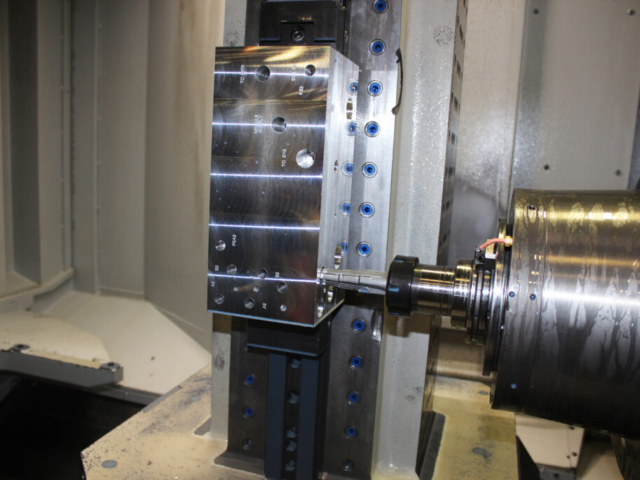

Production Machining

GK has the multi-axis machining capabilities for large production runs of metal parts and pieces:

- Bar Fed Lathes – supports bar stock to reduce vibrations that can transfer to the part, and helps to speed the change over process

- Multi-Part Mill Fixtures – we have the ability to set several parts at various orientations in one setup to help speed cycle times

- Choose from a variety of materials, hardware and fasteners – GK keeps a large inventory of raw materials in-house

- Choose from a variety of paint and powder coat colors to fully finish your custom metal part or pieces

Prototype Run

Manufacturing prototype parts fast and cost-efficiently is often a balancing act of quick-turn, CNC machining capabilities and an optimized part designed for those capabilities. Important considerations are reviewed when designing parts for GK milling and turning processes that can accelerate production time while reducing costs. Our team of expert machinist can assist you with the design of creating a metal prototype part.

- We provide prototyping services, GK can create concept models and apply various functions

- Prototyping via CNC machining delivers high speed, high precision, and robust part manufacturing solutions

- With years of manufacturing experience, our experts offer the best solution for all your manufacturing needs

GK MANIFOLDS FROM CONCEPT TO COMPLETE MANIFOLD

GK offers custom design and manufacturing services for hydraulic manifolds. Many customers have systems with unique fluid power needs that they require custom solutions. Custom hydraulic manifolds that regulate fluid flow between pumps and actuators and other components in a hydraulic system need to be designed with efficiency in mind. A complex matrix of variables can make manifold design complex. Custom applications are not the same as buying off the shelf.

The Process:

- Quoting – Specialized software for quick, consistent, and competitive quotes

- Engineering – Highly skilled engineers with many decades of design experience

- Programming – Utilizing advanced CNC software for dependable accuracy

- Machining – Talented machinists with many decades of experience

- Cleaning & Deburring – Inspect, clean, de-burr, and contamination-free

- Assembly – Under exact standards with stringent processes and procedures

- Testing – Dynamic and static testing of assembled manifolds and reporting

With today’s efforts being towards energy efficiency, it is important that the hydraulic system is as efficient as it can be. A properly designed and manufactured hydraulic manifold can make a system more efficient, easier to maintain, and easier to troubleshoot. Whether you are looking for a one-off custom manifold for your project or 50 manifolds; GK Machine will strive to meet and exceed your needs with quality, customer service, and on-time delivery.

Machining Capabilities:

DMG MORI NT5400/1800SY: Production Milling Machine with 5 axis mill-turn with lower turret

DMG MORI NHX6300: Production Milling with 4-axis horizontal machining center

DMG MORI CTX BETA 1250TC: Turn Mill with 5-axis and 60” bar feeder

MORI DURAVERTICAL 5100: Production Machining with 3-axis vertical

MORI NXL 2500/700SY: Production Mill Turn with 4-axis machining center and 48” bar feeder

Materials: Aluminum, Stainless Steel, Steel, and Ductile Iron

GK’s custom manifolds are built to your exact measurements and specifications. We can design an efficient, highly functional product that meets your specifications for prototype and production manifold solutions. GK’s Engineering Team will work closely with you at every step in the process, from the design and prototype stages through full production; to help ensure that your manifold matches your specific requirements.

Shipping Service

A wide range of shipping methods:

The GK team works with you to determine the best option for your shipment. We’ll help choose the option that meets your timeline and your budget.