GK is a reliable, quick-turn supplier of machined metal components with unmatched in-house capacity to ensure parts and pieces are shipped on-time. At GK Machine, our ISO-9001 certified CNC machining facilities are designed for both low-volume and high volume production runs. GK continues to invest in the latest machining centers and advanced software for the purpose of continuous improvement and to be a leader in machining technology. GK Machine has the expert technicians on staff with education and training on CNC processes and procedures to meet high standards of excellence in precision machining.

With state-of-the-art machines to design, create and manufacturer metal products, GK offers a wide variety of services:

- Laser Cutting, Plasma/Flame Cutting

- Metal Forming

- CNC Machining

- Welding & Fabrication

- Integrated Electrical and Mechanical Assembly

- Finishing (Prep, Acid Wash, Paint & Powder-Coat)

Machine Specifications:

GK Machine utilizes some of the most flexible and state-of-the art machines on the market today. We provide customers with fast and efficient metal parts, pieces and components. With live tooling and both vertical and multi-axis horizontal CNC milling and turning centers, GK consistently produces accurate, high quality results.

CNC Milling

GK’s CNC Milling process produces metal parts and pieces fast and efficiently. GK utilizes both vertical and multi-axis horizontal CNC milling centers to consistently produce accurate, high-quality results.

With machined production parts, customers receive competitive pricing at higher quantities in addition to first article inspection, reporting and certifications. GK utilizes 3-axis milling, 4-axis and 5-axis indexed milling processes to manufacture parts from a variety of various metal materials as well as some plastic materials.

GK utilizes some of the most flexible and state-of-the-art machines on the market today. The process of CNC Machining with live tooling has improved efficiency and accuracy of the metal part making process. GK has CNC machining capabilities on a number of machines and able to provide quality parts to meet your production demands within tolerances of .0005+/-

![]() CNC Milling Machines

CNC Milling Machines

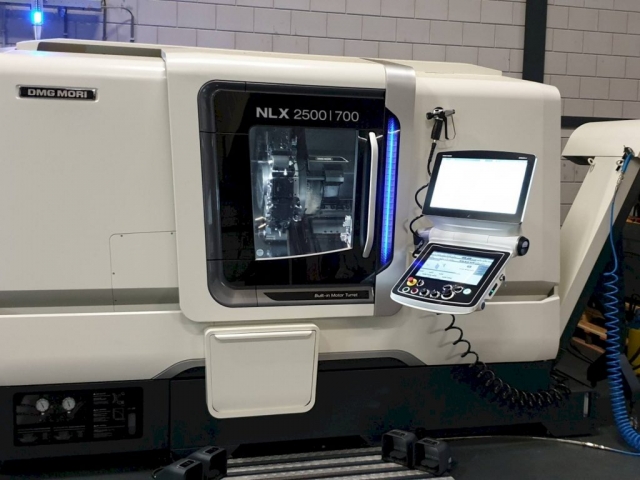

CNC Turning

GK’s CNC Turning process produces custom end-use production parts quickly and efficiently by using the latest technology driven machines on the market. We use CNC lathes with live tooling which decreases setup time and part handling while improving accuracy, precision diameter and critical depth tolerances.

GK offers a wide variety of CNC turning services, ranging from basic single spindle, two-axis lathes up to multi-spindle five-axis lathes, each with live tooling. GK’s CNC Turning center produces axial and radial holes, flats, grooves and slots – all can be machined with ease.

CNC Turning Machines

Manual Machining:

Why Use Manual Machines? While CNC Machining is usually the best way to create a part, there are times when using a manual mill or lathe is more appropriate. In addition to our CNC equipment, GK Machine can create parts with manual mills and lathes.

Manual machining is the predecessor of CNC machining. The equipment is similar, but without the computerized controls. So, when is manual machining appropriate? In our experience, it may work best with: repair work, low quantities, variations between parts, or the part needs to look handmade.